The cycle of materials is a global phenomenon, with Earth being the source of all materials and the ultimate reservoir. Through beneficiation, purification, refining, pulp manufacturing and other processes, raw materials are converted into useful industrial materials such as metals, chemicals, and paper. These bulk materials are then modified to become engineering materials that meet performance requirements. Manufacturing processes are used to shape and assemble these materials into useful end products.

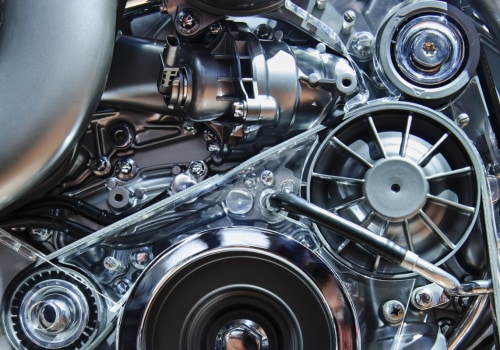

Once their useful life has ended, these products are returned to the earth as waste or dismantled and recovered for basic materials. At the same time, advances in solid-state physics and chemistry have provided a common guide to what once seemed disconnected problems in materials development. Alternative fuels such as animal fats can be used in diesel engines due to their good combustion properties, reduction of pollution, and the possibility of using them in their raw state in blends with diesel fuel or as biodiesel. The diesel engine of a D2156 truck is powered by preheated raw animal fats mixed with 5% and 10% diesel fuel. Injecting alcohol into the intake manifold of the diesel engine ensures a poor but homogeneous mixture of fuel in the combustion chamber, which reduces polluting emissions while maintaining engine performance.