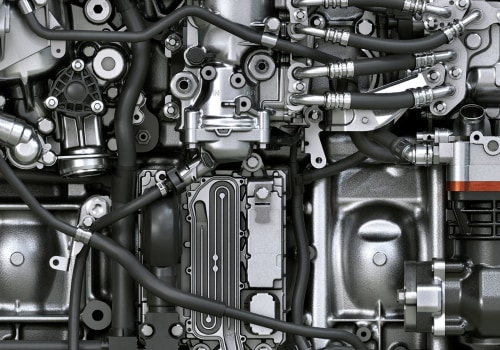

The emission control system in cars is a means of limiting the release of harmful gases from the internal combustion engine and other components. The component responsible for controlling the flow of exhaust gases destined to re-enter the intake stream is the EGR valve. There are two types of EGR valves, on the cold side and on the hot side, and the type of activation varies from pneumatic to hydraulic and electric (the latter being the most common today). The EGR valves on the cold side direct exhaust gases to the intake after they have left the EGR coolers. An EGR valve on the hot side performs its flow functions before EGR coolers.

This type of valve is believed to help reduce the accumulation of soot and dirt that causes valve failure (i.e., when exhaust gas temperatures exceed 1200 degrees F in most engine applications, the portion of the exhaust gas that is returned to the intake duct must be cooled). The task of lowering these temperatures is performed by an EGR cooler, an air-liquid heat exchanger that uses the engine's circulated coolant. In engines such as the 6.4 L Power Stroke and the 6.7 L Power Stroke, there are two EGR coolers in operation. Diesel exhaust fluid (DEF) is a non-flammable fluid composed of 33% ammonia-based urea and 67% purified water. DEF is used with diesel engine exhaust systems to reduce emissions by converting nitrogen oxide (NOx) into nitrogen and water vapor. DEF technology has a proven track record, as it has been used in Europe for years.

Diesel particulate filters can capture up to 100% of particulate emissions and are responsible for preventing black particles from accumulating in modern diesel engine exhaust pipes. These include a diesel oxidation catalyst (DOC), a diesel particulate filter (DPF), an exhaust gas recirculation (EGR) system and a selective catalytic reduction (SCR) process. The diesel oxidation catalyst (DOC) is placed just in front of the DPF can. The disadvantage of SCR is its greater complexity compared to other diesel exhaust gas aftertreatment systems, as well as DEF freezing before diesel fuel does. Miller's modification of the diesel engine is another means of reducing NOx, and it is believed that Caterpillar uses it for its ACERT diesel.

The diesel oxidation catalyst, or DOC, is essentially the diesel equivalent of a gasoline engine's catalytic converter. Diesel particles, often abbreviated as DPM, refer to soot emitted after diesel fuel is burned. The soot collected by the DPF periodically triggers a regeneration cycle (more on this later), which consists of combining diesel fuel and exhaust gases inside the DOC that transforms soot into fine ash. Both the 6.7 L Power Stroke diesel engine and the 6.6 L Duramax diesel engine meet strict emission standards required by federal government regulations through a sophisticated network of interlocking emission control devices.